The H-IIA launch vehicle is the workhorse that has provided

Japan with reliable, independent and guaranteed access to

space since 2001.

As the first step toward the National Flagship Launch System

in the next generation, the H-IIA upgrade project aims at

improving the vehicle’s geostationary transfer orbit (GTO)

mission capabilities and payload environment conditions. This

will enable Japan to promote R&D and utilization of space, as

well as to enhance the international competitiveness of the

H-IIA launch vehicle.

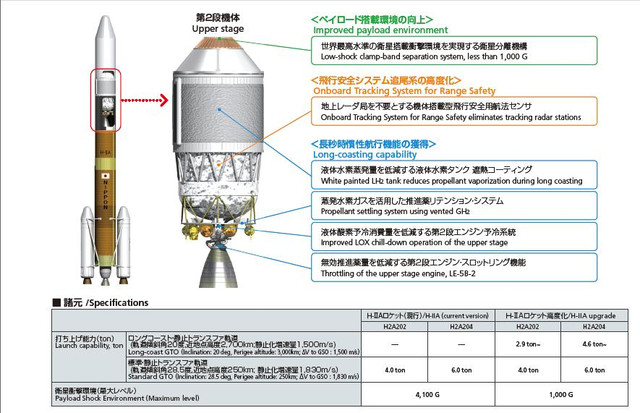

The H-IIA upgrade project focuses on upper stage modifications to

provide better services for customers. The development will be

completed by 2013 to bring the vehicle to market as quickly as

possible.

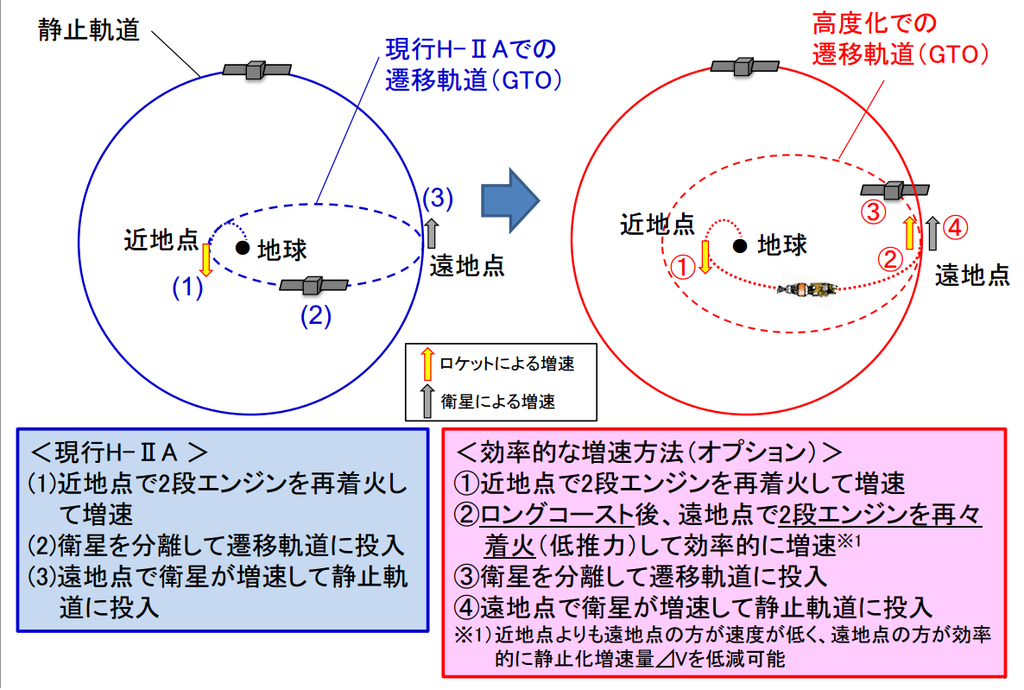

1 Long-coasting capability

The coasting duration of the H-IIA upper stage will be enhanced

from one hour to five hours by improving cross-cutting cryogenic

propulsion technologies. This will enable to inject a spacecraft closer

to geostationary orbit (GSO) than our current standard transfer orbit to

extend the fuel life of satellites, while also extending limited launch

windows for planetary exploration missions.

Japan with reliable, independent and guaranteed access to

space since 2001.

As the first step toward the National Flagship Launch System

in the next generation, the H-IIA upgrade project aims at

improving the vehicle’s geostationary transfer orbit (GTO)

mission capabilities and payload environment conditions. This

will enable Japan to promote R&D and utilization of space, as

well as to enhance the international competitiveness of the

H-IIA launch vehicle.

The H-IIA upgrade project focuses on upper stage modifications to

provide better services for customers. The development will be

completed by 2013 to bring the vehicle to market as quickly as

possible.

1 Long-coasting capability

The coasting duration of the H-IIA upper stage will be enhanced

from one hour to five hours by improving cross-cutting cryogenic

propulsion technologies. This will enable to inject a spacecraft closer

to geostationary orbit (GSO) than our current standard transfer orbit to

extend the fuel life of satellites, while also extending limited launch

windows for planetary exploration missions.

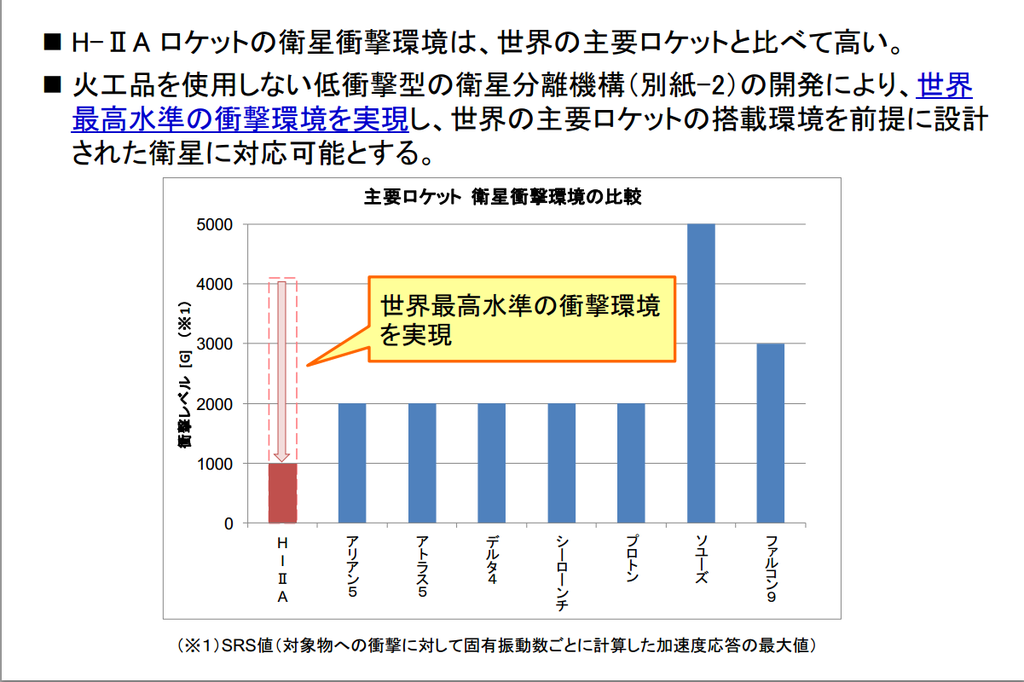

2 Improved payload environment

The payload shock environment will be reduced from 4,100G to

below 1,000G by a non-explosive clamp-band separation system. This

allows sensitive equipments to be located closer to separation plane

and problems with current pyrotechnic release devices will be

mitigated.

The payload shock environment will be reduced from 4,100G to

below 1,000G by a non-explosive clamp-band separation system. This

allows sensitive equipments to be located closer to separation plane

and problems with current pyrotechnic release devices will be

mitigated.

3 Onboard Tracking System for Range Safety

An onboard navigation sensor for range safety will be demonstrated

that provides navigation data for range safety without tracking

radar stations. This concept is intended to minimize the ground

infrastructure and reduce cost of operation and maintenance.